Set Up the Indoor Unit Condensate Piping Connections for Quantum Ultra Floor-Ceiling Flex (UYT-24) SystemsUpdated 13 days ago

Introduction

This article explains how to set up the indoor unit condensate piping connections for Quantum Ultra Floor-Ceiling Flex (UYT-24) systems.

The article explains how to install the flexible hose for the condensate piping, as well as its connection procedure. In addition, the article explains the heat insulation process and how to ensure a continuous downward pitch. .

Drain Pipe & Insulation Material Requirements

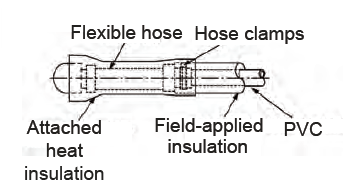

- Drain pipe: Polyvinyl chloride (PVC) pipe with an outer diameter of approximately 1-1/4 inch (32 mm).

- Heat insulation: Foamed polyethylene insulation with a maximum thickness of 3/8 inch (9.5 mm).

Install the Flexible Hose

- Measure the diameter of the hard pipe using a pipe cutter, and adjust the joining angle as needed.

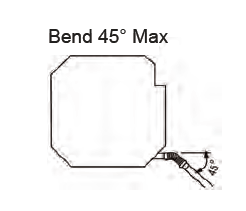

- Extend the flexible hose to the required length without deforming excessively as shown in the illustrations.

- Use the provided hose band to secure the flexible hose firmly.

- Install the flexible hose in a horizontal orientation to ensure proper drainage. The maximum bending angle is 45°.

Connection Procedure

- Connect the transparent flexible hose to the polyvinyl chloride (PVC) drain pipe.

- Apply PVC adhesive to the connection point between the drain pipe and flexible hose, ensuring a watertight seal.

- Apply the adhesive approximately 1.5 inches (38 mm) from the end of the PVC pipe, then insert it into the flexible hose.

- Allow at least 10 minutes for the adhesive to cure. Do not apply pressure to the joint during the drying period.

Heat Insulation

- Wrap the entire length of the flexible hose carefully with the provided insulation material, starting from the flexible hose and continuing to the indoor unit connection.

- Ensure that there are no gaps or exposed sections. This could potentially cause condensation.

- If necessary, use additional field-supplied insulation material to fully cover all piping and connections.

Continuous Downward Pitch & No Kinks

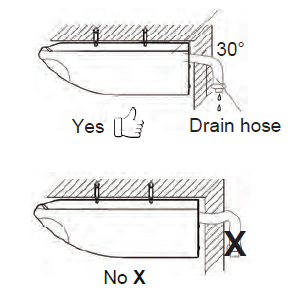

- Ensure that the drain hose slopes downward all throughout with an angle of 30° to prevent back flow.

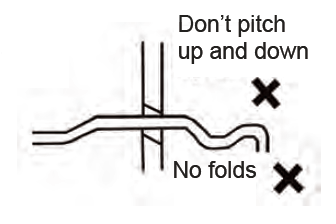

- Make sure the hose does not have any kinks or points of upward flow throughout the entire channel.

- Maintain at least a 2-inch (50.8 mm) gap between the drain outlet and final termination point (ground, grass, etc.)

After the System Installation is Completed

Check the condensate drain line for leaks, and ensure that it drains properly. If a field-provided condensate pump has been installed, make sure it operates properly. Pour water into the drain pan through the inspection port to confirm flow.

Notes

- Insulate all drain piping and connections to the indoor unit to prevent dew formation and dripping.

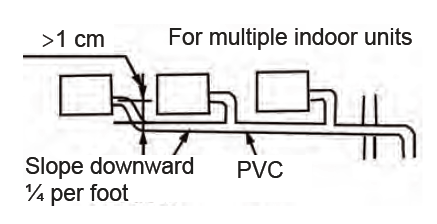

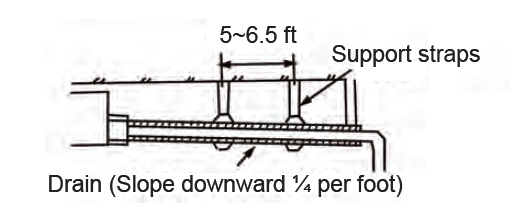

- Maintain a continuous downward slope of less than 1/4 per foot (76 mm), with no dips, sags, or reverse slopes. The minimum slope ratio is 1/50.

- Install support straps/brackets every 5-6.5 feet (1.5-2 m) along horizontal runs to maintain proper slope and prevent sagging.

- Keep the total horizontal pipe length under 65 feet (20 m).

- If installed side-by-side, maintain a gap of approximately 3/8 inch (9.5 mm) between parallel pipes.