Leakage Inspection & Vacuuming for Refrigerant LinesUpdated a month ago

Introduction

This article explains how to check for leaks in refrigerant lines and perform a vacuum test.

Use the valve of the copper welded pipe installation for leakage inspection and vacuum pumping. Using a separate suction port in this process will lead to refrigerant loss.

Check for Leaks

There are two methods for checking for leaks in refrigerant lines.

The first option is using dry nitrogen to pressurize the refrigerant line and evaporator coil to 250 PSIG.

Pressure test the field pipework with an inert gas after completing the field piping for the system. The minimum test pressure for the system must be the low-side design pressure. See the nameplate for details.

The alternative option is using soapy water or bubbles at each brazing position to check for leaks.

After checking for leaks, vacuum test the field piping prior to refrigerant charging.

Vacuum Test

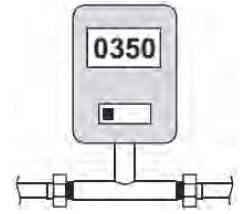

- Evacuate until the micron gauge reads no higher than 350 microns, then close the valve to the vacuum pump.

- Observe the micron gauge. If the micrometer does not rise above 500 microns within 1 minute, the evacuation is completed.

- After the evacuation, turn off the vacuum pump and micron gauge.

- Close the valve on the manifold instrument cluster.